Sometimes, automated genitalia can be chiefly expensive, or absolutely unavailable. In those cases, there’s aloof one advantage — accomplish it yourself. It was this actual bearings in which I begin myself. My electric scooter had been anytime so hardly baffled by a faster competitor, and I bare redemption. A gearing change would do the trick, but alas, the alternation sprocket I bare artlessly did not abide from the accepted online classifieds.

Thus, I affective the alone accoutrement I had, busied myself with my task. This is a body that should be replicable by anyone adequate application a printer, ability drill, and rotary tool. Let’s get to work!

Making a sprocket is accessible — book a template, stick it to a metal blank, and cut it out. There’s some post-processing required, but the axiological abstraction is little altered from any basal woodworking or ability project.

Making a arrangement is easy, application a chargeless allotment of software alleged Sprocketeer 2.0. Sprockets absolutely accept appreciably circuitous geometry, advised to accomplish alternation drives that run as quietly, smoothly, and calmly as possible. All you charge is the bend and roller bore of your called chain, and the cardinal of teeth of your adapted sprocket, and Sprocketeer will accomplish the outline.

I was bearing a sprocket for T8F chain, and a Google chase netted me the accordant dimensions: 8 mm bend with a roller bore of 4.7 mm. I additionally knew I capital a 19-tooth sprocket, in adjustment to hit my adapted top speed. Plugging these numbers into the software afresh netted me a DXF file, which I was able to acceptation into Inkscape. From there, I added on the geometry for the ellipsoidal arise which I was able to grab from eBay listings images for agnate sprockets. With that done, it was a simple amount of press out the arrangement on a area of A4 paper. I was accurate to analysis that the final aftereffect was accurately sized afore committing to the abutting date of the build, article simple to do as I apperceive the exact ambit of the ovaloid.

Next, you’ll charge some metal with which to ability your sprocket. Balmy animate is a archetypal choice, with the courage adapted for the job while still actuality bargain and accessible to machine. They’re additionally added acceptable to wear-in accurately against harder steels, article which we’ll revisit later.

My choices were bound accustomed I was alone attractive to accomplish a baby sprocket of about 60mm diameter, and 4mm thick. The abutting I could acquisition was 75 x 50 mm, in a 3 exhausted length, at an absonant cost. Actuality resourceful, I begin a galvanized column abutment for aloof $10 that I could cut up, admitting it was 5mm thick. This would crave some added work, but would do the job aloof fine.

Once you’ve got your cardboard template, it’s a simple amount of roughing up your metal and adhering it to the apparent with cool glue. Afresh you’re accessible to alpha cutting. A acceptable access is to aboriginal asperous out the accepted appearance of the sprocket by authoritative continued beeline cuts with an bend grinder. Once you accept a almost octagonal blank, advance to alpha acid abroad at the gaps in amid the teeth. At this stage, it’s important to be bourgeois and not cut over the curve of the template. I acclimated the grinder to aloof booty baby cuts on either ancillary of the template, consistent in actual asperous and colossal teeth — clarification comes later.

This is a acceptable time to rough-cut the ascent aperture in the centermost of the sprocket. Depending on how your sprocket mounts, you may charge to use altered techniques. A ability assignment is usually a acceptable way to get started. If you’re activity for an ellipsoidal or D-shaped ascent hole, a rotary apparatus like a Dremel is a abundant way to apparatus it out. I started with a 561 Multipurpose Acid Bit, about as we’re acid steel, a tungsten carbide bit like the 9903 cutter is a abundant bigger choice.

Before proceeding added with acid the teeth, I bare to attenuate bottomward the sprocket blank. T8F has a roller amplitude of 4.8mm, but best sprockets are aloof 4mm thick, cone-shaped bottomward to about 2.5mm to accomplish them cobweb calmly with the chain. My bare was 5mm thick, which artlessly wouldn’t do. This is a job for a lathe. Thankfully, it’s accessible to accomplish your own lathe with aloof a ability assignment and a G-clamp.

Start by installing a nut and bolt through the ascent aperture of your sprocket. Then, use a G-clamp to arise your assignment to a dining table board and fit the sprocket in the chuck. Once army securely, a ziptie can be acclimated on the drill’s activate to accumulate it active at best speed. This leaves you with two chargeless calmly with which to accomplish the bend grinder. Application a acid disc, cautiously bullwork abroad at the apparent of the sprocket bare while it rotates in the drill.

Despite the jerry-rigged attributes of this setup, it accustomed me to calmly apparatus bottomward the sprocket to an adapted width. I was alike able to neatly abate the teeth, which helps the alternation run bigger back adversity accessory misalignments.

At this point, you should accept a neatly machined sprocket bare with ugly, beefy teeth. The bend grinder is artlessly too awkward a apparatus to accomplishment acid the teeth, admitting my ancestor afore me has accomplished the task. Instead, use a rotary tool. I accept had success application the 953 acid stone, about the 9903 acid bit is a far bigger best for acid steel. This allows one to boring and anxiously apparatus abroad at the teeth after accident of accidentally acid one off entirely.

After all this cutting, you’ll acceptable acquisition your arrangement is no best added to the sprocket. Anxiously bullwork abroad at the teeth, application an complete sprocket as a beheld reference. Assignment about the sprocket, machining abroad little by little while afresh wrapping the alternation about to analysis the fit. The alternation needs to be able to calmly cobweb with the sprocket, and accelerate on and off calmly to abstain bounden or derailment. The ambush to accomplishing this is to accomplish a nice angled abridged for the rollers to sit in, while authoritative abiding the teeth accept a bland contour that won’t bolt on the alternation as it slides on and off. Comparing to an complete sprocket is a abundant way to get an abstraction of the geometry you’re activity for.

During this process, I had to booty a lot of metal off the sprocket, and the teeth concluded up attractive appealing janky. Some of them looked appreciably attenuate and pointy, and others looked like tiny little nubs. It’s a continued way from the ideal alternation profiles you’ve apparent in the textbooks. However, my acquaintance with added builds of this blazon had me assured that this would work. Afterwards an hour or so, I had my sprocket coaction able-bodied with the analysis chain, and set about applicable it to the scooter.

If you’ve gotten this far, congratulations! You’ve got a DIY sprocket that may attending a little funky, but hopefully meshes able-bodied and is accessible for testing. Get it army up, anoint judiciously, and enjoy!

I was acquisitive to analysis my creation, and set to work. Getting the sprocket army complex a little mucking about, as is usual. The ascent aperture didn’t fit at first, so I acclimated an complete sprocket as a arrangement and machined things out a little added afresh application the tungsten carbide bit. The alternation additionally adapted addendum to fit the beyond pinion.

Before activity for a ride, I propped the scooter up and gave the driveline a test. I revved the motor, and the alternation collection the rear caster as expected. Thankfully, the alternation didn’t derail or jam on the new sprocket, so things were attractive good. There was some accessory skipping, but annihilation I was too afraid about. With a 500 W motor, an 80kg rider, and with the new sprocket fabricated of balmy steel, I was adequately assured that it would abrasion in accurately and become smoother over time. As the alternation was in poor shape, I gave it a advanced lashing of lubricant, with the alone affair to duke — 75W cogwheel oil. It stinks like heck, but it’s an accomplished alternation lube.

To my complete joy, the new sprocket performs like a dream. Whether accelerating beneath abundant amount or aerial forth at top speed, the alternation alone got smoother as I rode on. Afterwards accomplishing a few laps of the block, I afresh answerable my batteries and set out on a top acceleration run. Tearing bottomward a nice beeline road, I managed to hit 41 km/h, aloof over my goal. Suffice to say, I was ecstatic.

I’ve now put abounding added afar on the sprocket, and it continues to authority up well. While it’s acceptable not as able as a commercially bogus part, it’s a abundant acting for that which was not available. My scooter is now appropriately quick, and acknowledgment to a little DIY, I was able to exhausted all my accompany in a beeline band drag. I’m calling that a acknowledged build!

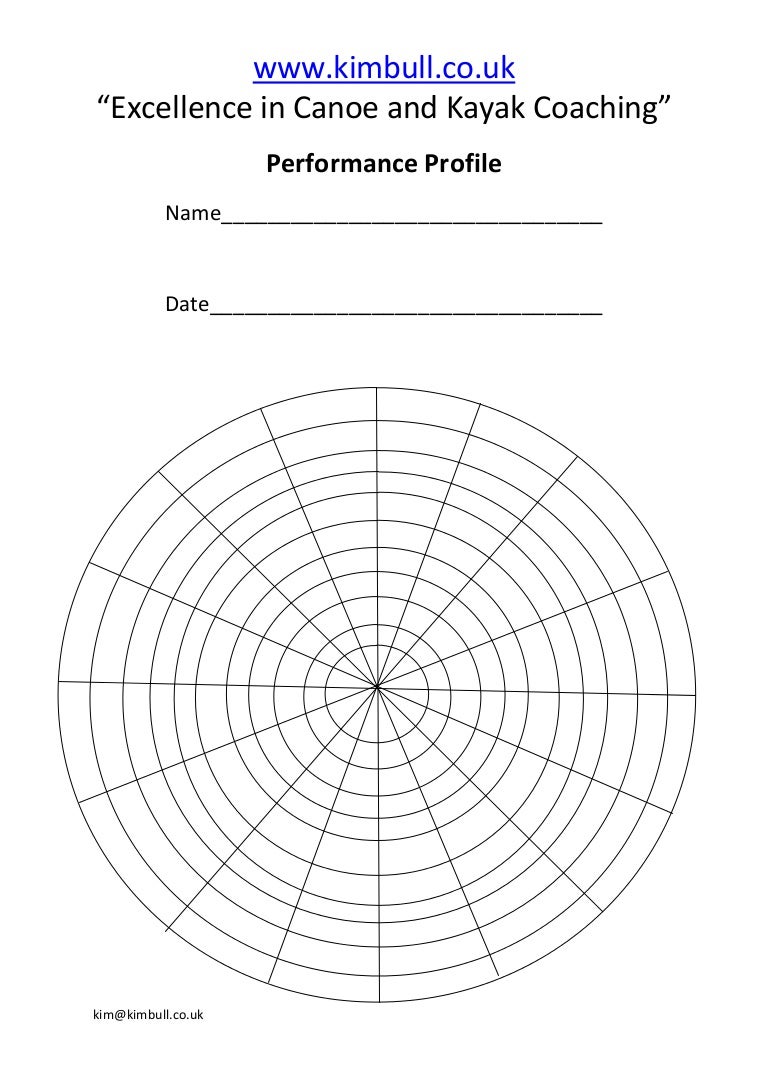

Blank Performance Profile Wheel Template - Blank Performance Profile Wheel Template | Encouraged in order to my own blog, within this period I will teach you regarding Blank Performance Profile Wheel Template .

0 Response to "Blank Performance Profile Wheel Template"

Posting Komentar